Recently I got the chance to review two masks using rather unique filters. These masks, Bloo Mask and MetaMask both stood out to me as the filters that they use are unlike any that I have tried before. They were extremely light, easy to breathe through, and blocked odours better than I have ever experienced with a cloth mask.

This led me to wonder – what is it that makes these filters (created by Revolution Fibres) so amazing? After reading through the website, I learnt a lot. However, I still had some questions. With that in mind, I reached out to Revolution Fibres to ask if they would be interested in having an interview.

Not only have I quickly become a big fan of their technology, but they are also based in New Zealand – my home country. I was very excited when they replied to me saying that they would not only be interested in answering some questions but that they would be more than happy to!

In this article, I want to share the interview that I had with the team at Revolution Fibres. Since I know that not all of my readers are familiar with the fields of nano-technology and masks, I started with some background questions to learn a bit more about the company and what they do. Further on, I asked some more technical questions that were asked by my readers or were simply curiosity on my behalf.

The article has greatly condensed as many of the questions and answers were very long. This is my first time putting together an interview-style article, so I apologise if it’s not perfect. All images in this post were sourced from Revolution Fibres.

This post contains affiliate links. For more information, please refer to my affiliate disclaimer.

Information on this blog is for informational purposes only. Readers are encouraged to confirm the information herein with other sources. Furthermore, this information is not intended to replace medical advice from professionals. This website assumes no responsibility for the accuracy of the information, which is subject to change without notice.

Introduction

1) What/Who Is Revolution Fibres?

Revolution Fibres is a company that was founded back in 2009. The original intention of the founders was to create the world’s best air filter, however, along the way they came across nanofibre. Seeing the capabilities of such fibres, they were instantly interested in the many applications of such technology.

The issue was that there were no manufacturers in New Zealand capable of creating what the company needed and they were forced to come up with another solution. That solution was to create the nanofibres themselves. Over time, the team at Revolution Fibres developed a process named Sonic Electrospinning™.

Along the way to creating the world’s best air filter, many new applications for nanotechnology were found, and now Revolution Fibres has many different products and their technology can be found in many different industries. Although this article focuses on filters used in masks, Revolution Fibres is also active in many other industries.

Some of the other nanofibre-based products that Revolution Fibres has created can be seen in the image above. Activlayr is a marine collagen delivery platform using nanofibre to produce skincare face mask, Seta filters are used for air filtration, and Phonix is a nanofibre acoustic technology that can be used in furniture or in roofs and ceilings. These are just a few of the fields that Revolution Fibres work in, but it shows just how many fields can benefit from nanofibre technology.

Since the pandemic, Revolution Fibres are also fortunate to get funding from NZ Government on the Covid-19 Innovation Acceleration Fund (CIAF) to expand on our R&D to take a step further by discovering new membranes suitable for N95 to N99 to meet the worldwide shortages of facemasks and in vital materials such as melt-blown which now typically found in the mask market.

2) What Is Nanofibre?

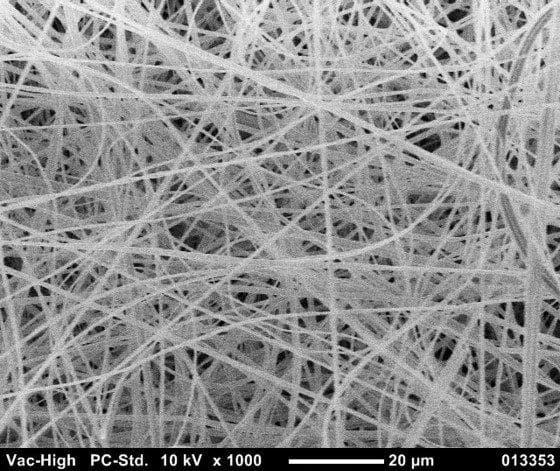

Nanofibre is a textile made from extremely fine fibres, typically 100-300nm in width (1/500th the width of a human hair) which can be made from a wide variety of polymers. These fibres are spun into layers, and these layers are put together to form filters.

Revolution Fibres sees nanofibre as a platform technology, offering major advantages in a diverse array of applications. Even though it is more expensive than the typical melt-blown nonwoven filters in the market it is more functional and breathable.

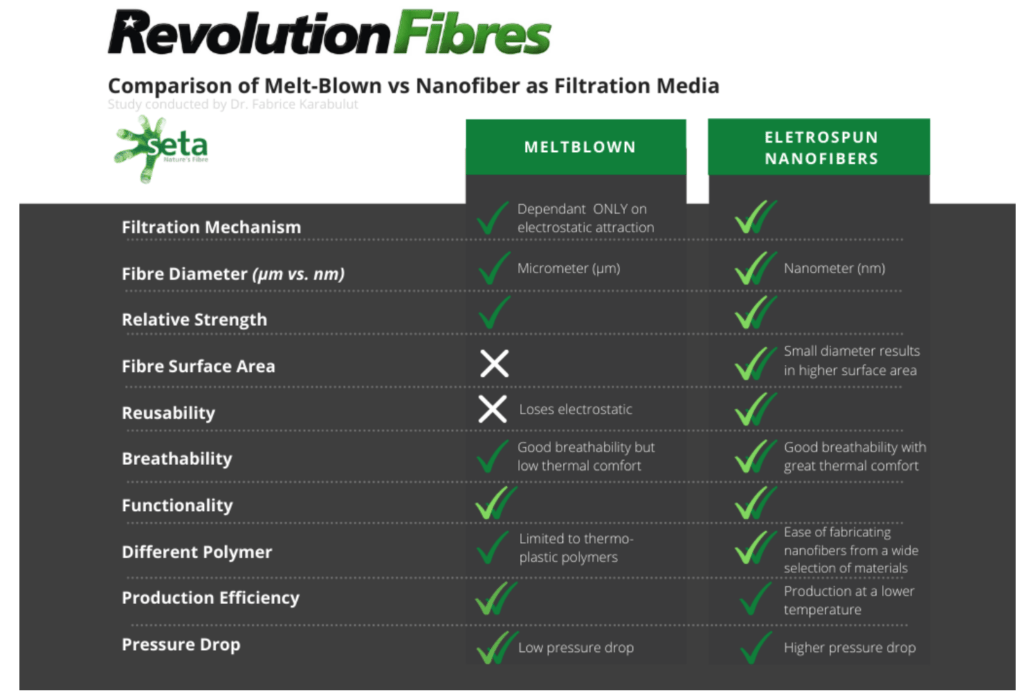

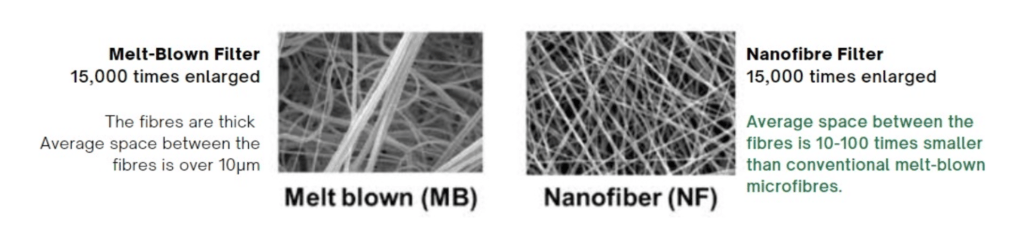

Melt-Blown masks are the industry standard due to generally being cheaper to produce. Nanofibre filters, though, use fibres that are 10-100 times smaller than conventional melt-blown microfibres. This means that nanofibres have a very large surface area and small pore diameter. This leads to not only high filtration but also more reusability and breathability.

Revolution Fibres Filters

3) What Makes Seta Filters So Unique?

As previously mentioned, Seta filters are electrospun nanofibre filters as opposed to Meltblown filters. This means that the filters are generally more breathable and are more reusable.

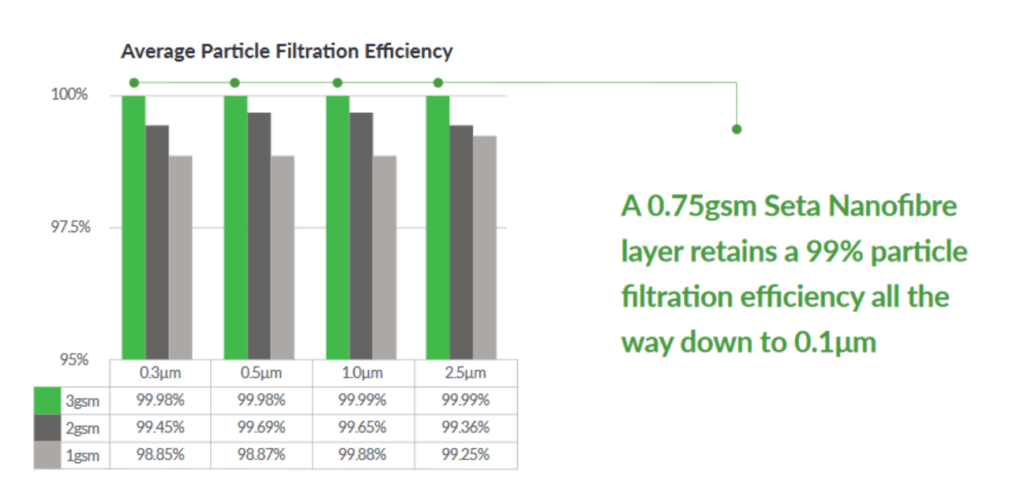

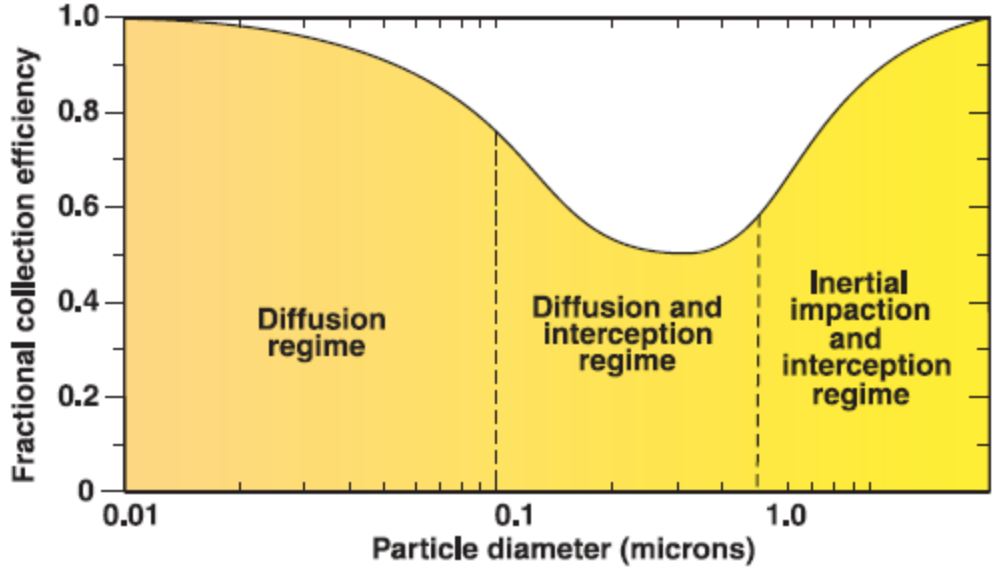

Seta filters have also been shown to have highly effective filtration all the way down to 0.1um particles due to not only having smaller fibres and pores but due to the extra filtration mechanisms that these filters use. Where melt-blown filters often rely very heavily on electrostatic filtration, nanofibre masks have a wider range of filtration mechanisms to rely upon.

What this means is that nanofibre filters tend to retain much higher filtration capabilities than melt-blown masks over time. Electrostatic capabilities are largely lost after the mask is washed or once it gets damp from breathing. While nanofibre masks lose some filtration, they often retain a far higher filtration efficiency and are therefore more reusable.

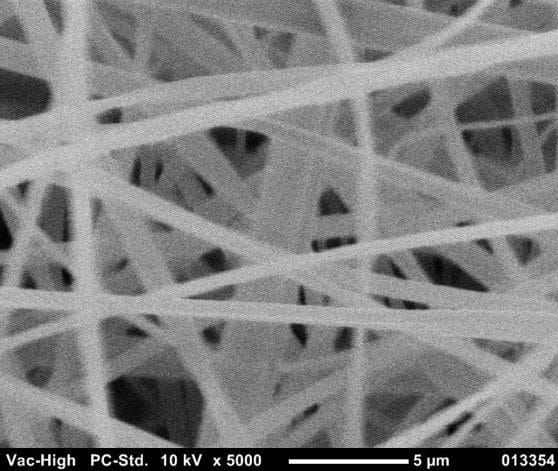

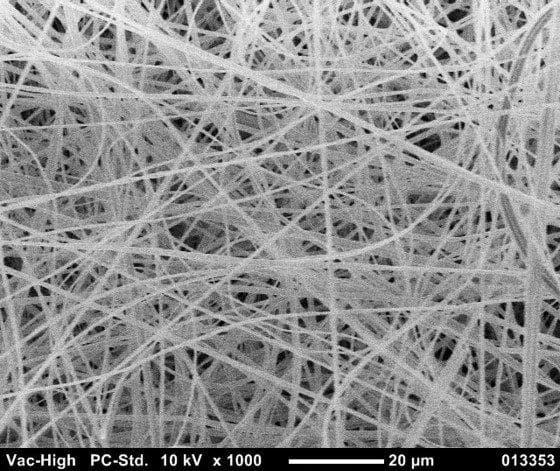

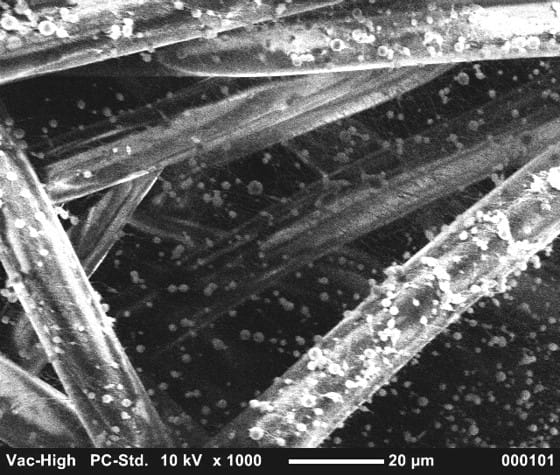

Compared to other nanofibre filters, Revolution Fibres makes some of the best on the market. The images above show a filter using Seta (right) and a nanofibre filter from another brand (left). As the images show, the nanofibres on the Seta filter are much more evenly dispersed, with less beading. Beading can lead to adverse effects on the air pressure drop for the filtration media.

Another aspect that makes Seta Filters unique is the carbon filter media that is used in the filters. Carbon filters are used to filter VOCs and organic odours and the carbon filters used in Seta filters are very capable. The Bloo Mask (using a Seta filter) was the best mask I have ever tried in regards to filtering smells and breathability.

4) How Are the Filters Made?

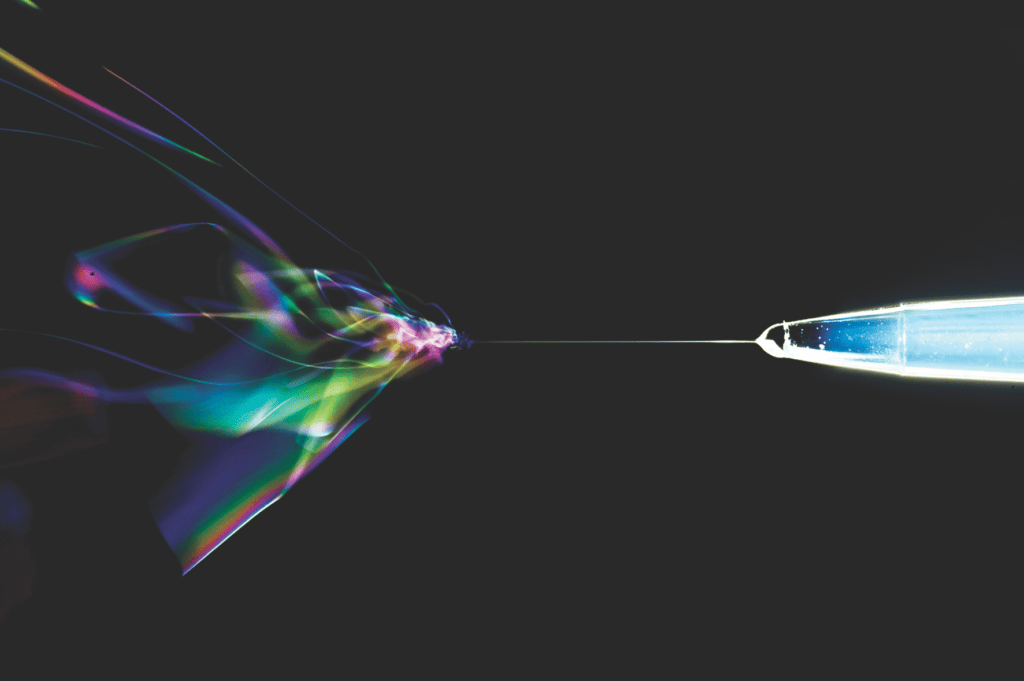

Revolution Fibre’s filters are made through a process called Sonic Electrospinning Technology™. The SETA membranes are made through a process called “electrospinning,” which involves dissolving a polymer in a solution and then using an electrical current to move a droplet of the polymer downward through a needle.

As the droplet accelerates, it stretches into a very small fibre that retains a static charge which is very beneficial and prevents you from inhaling viruses. From there, we can add any additive to the membrane with properties like antibacterial, antimicrobial or antiviral. Therefore making the additive be apart of the fibre itself – functional fibres.

5) What Benefits Does Using Sustainable Resources Bring?

Full question – I see that many Revolution Fibres products use natural materials such as manuka extract and other natural functional additives. Most other companies that I see making filters seem to use non-organic materials. What benefits does using such materials bring? Also, does it make the filters more environmentally friendly?

Answer – At Revolution Fibres, we love to challenge ourselves by creating products with sustainable resources meeting environmental, social and economic demands. We are ready to contribute to sustainable development with the expertise of nanofiber production at our fingertips.

Globally, the onus is on companies to reduce waste and priorities sustainability when developing or manufacturing products and fine-tuning our processes is proof this commitment must be ongoing.

As a manufacturer, using sustainably sourced and bio-derived materials is the first step to becoming a more sustainable business. It took years of research and significant technological advancements to enable Revolution Fibres to produce kilometres of nanofibre sheets daily without generating any waste.

There is no residue from the solvent used to make nanofibre because it evaporates fully during the high voltage sonic electrospinning process. We have tailored our machine in a way that we can facilitate natural/non-natural material.

There is no finish line when it comes to sustainability hence when it comes to natural vs. non-natural, natural material will be our priority.

Like most businesses we are constantly assessing how we can reduce our impact further, be it using more environmentally friendly materials or innovating to develop products that can help make a positive change.

Technical Questions

6) How Does Nanofibre Compare to Meltblown When Wet?

Full question – I see that one of the biggest benefits of nanofibre compared to meltblown is that it is more breathable, but also that it can be reused. I understand that this is due to the fact that on MB filters, the electrostatic charge is the primary filtration mechanism (which is lost upon washing).

However, on NF filters there are many other mechanisms in play (sieving, interception, inertial impaction, diffusion & electrostatic attraction) and that is why they are able to be washed and reused while retaining high filtration efficiency.

I was under the impression that these other mechanisms were present on both MB and NF filters and therefore, both should have some efficiency after being washed. Is this not the case? Or do MB filters simply rely far more heavily upon the electrostatic mechanism as they have fewer fibres present for the other mechanisms to occur?

Answer – MB relies far more heavily on electrostatic filtration which can be lost after 30 minutes when the user is breathing through the mask due to the moisture present in the breath. Fibre present on MB masks is larger than the ones present in NF (factor from 10 to 100). This led to a lower filtration efficiency for MB compared to NF.

The thinner the fibres are, the better. Other mechanisms occur like inertial impaction, diffusion, and interception that you mentioned.

7) How Many Times Can Nanofibre Filters Be Washed?

Full question – Building on this, has any testing been done regarding how many times NF filters can be cleaned before losing substantial efficiency? I saw that after 5 washes they still retain over 99.5% efficiency, but I wonder about 25 washes or more.

Answer – Unfortunately, in terms of the number of times – we internally have not verified it but it is in the pipeline.

We want to educate our customers to tell them that mask shells can be washed but to try and avoid washing filters. As you don’t know what kind of particles will be in the water you wash your filter/mask with hence it is hard to verify it.

What we do know is that virus-killing comes into play, with some technologies claiming to kill viruses/bacteria that land on the mask, but for how long? And once you wash it, does it still kill the bacteria that lands on the surface?

Well, what we do know is that with nanofibre we can let the functionality like antibacterial to be a part of the fibre – while others, as mentioned, lose electrostatic property or other coatings on the filter. It will neutralize the filter/mask itself.

8) Down to What Particle Size Are Filters (Such as Seta) Realistically Effective?

Full question – There is a common belief that since masks are tested with particles around 3 micrometres (I believe that Nelson Labs MPPS tests occur at 2.6-3 micrometers) they are only effective against particles this size and larger.

What many people don’t realise is that that size (the MPPS) is actually a worst-case scenario of filtering efficiency and that filters are actually more effective at filtering smaller particles due to diffusion coming into play.

This is particularly important recently as most viral particles are in the 10s of nanometers in diameter – far smaller than most masks/filters advertise filtration against. My question is, down to what particle size filters (such as SETA) realistically effective? Does filtration performance begin to drop off once particles become extremely small?

Answer – This is a great question! According to our VFE testing results from Nelson Labs, at 0.1um particle size, the Seta filter has an efficiency of 99.0%. While at 0.3um Seta result shows 98.86% efficiency. You realized in the global market with filtration media 0.3microns (um) is being promoted more than 0.1um.

This is because particles that small have so little mass that they actually get bounced around like a pinball when they hit gas molecules. So they move in random zigzag patterns – with these ultrathin fibres found in SETA will help ‘stuck’ in the layers of fibre we have there’s so many of them.

SETA is definitely more effective because of the thin the fibre in each substrate which helps bounce off these particles

9) What Leads to Decreased Breathing Resistance in NF Filters Compared to MB Filters?

Full question – What leads to decreased breathing resistance in NF filters compared to MB filters? If my understanding is correct, MB filters use far larger fibres than NF. However, MB filters also have larger gaps between the fibres whereas nanofibres are more closely packed. Since the gaps between the fibres in NF filters are smaller, would this not increase breathing resistance? I am curious as to why the opposite is true.

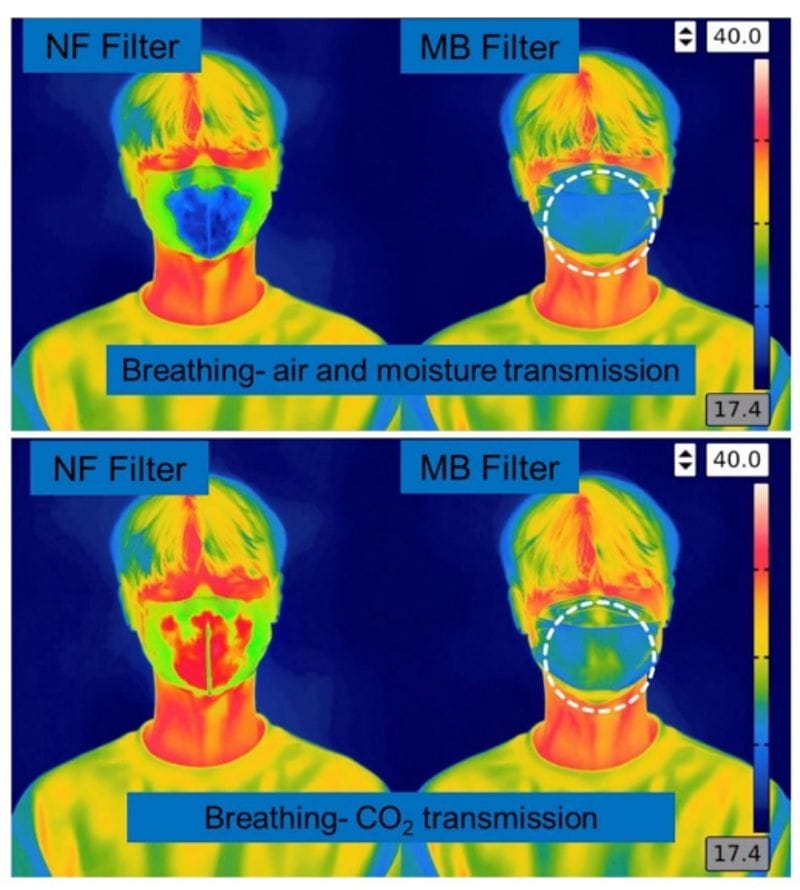

Answer – MB filter is not homogeneous with also large and non-uniformed pores. Having a non-uniform filter led to low moisture and CO2 transmission (see White paper).

Pressure drop for NF is comparable with MB, but this doesn’t mean that breathing is more comfortable. NF has multiple uniform layers with smaller pores allowing for excellent CO2 and moisture transmission. Depending on the type of material used for NF filter and GSM, pressure drop can be sometimes slightly higher than MB. However, breathing comfort is excellent compare to MB.

10) Does Moisture Lower Nanofibre Filtration?

Full question – Although I haven’t been able to find much research on the topic, I believe that filtration efficiency drops when the filter media becomes damp/wet. Firstly, is this true? Secondly, do NF filters perform differently compared to MB when damp/wet? I am guessing that this has something to do with electrostatic attraction, so I am curious if NF performs better.

Answer – You got the concept there, but this totally depends on the type of material you are when using for the NF filter. It varies on what formulation you put together when you’re spinning that nanofibre.

11) Can You Discuss More About the Filter Additives That You Plan to Add?

Full question – You mentioned (question 4) an additive to kill bacteria/viruses that is in the works. I am not sure how much you are able to discuss this, but I am wondering if it will be able to kill viral particles immediately, or will this occur over a duration similar to other competing products?

Answer – Unfortunately, I am not able to go into too many details on this as it is in our product development pipeline but what I can tell you is that the next SETA will have antimicrobial properties that have the ability to eliminate/neutralise bacteria, viruses, protozoans, & fungi. This is because of our new formulation and how we can add function to be a part of the fibre – while other media like MF will lose its function as it is just a coating on the filter media.

We are heavily invested in the world’s best test rig – PALAS. This would help us reposition Seta and our upcoming Seta pipeline. With this kit, we can verify the quality of the filter and mask for our customers and fight against the counterfeits in the market.

12) Is There a Common Misconception You See Regarding Masks/Filters?

Full question – Finally, as experts in the field I wonder if the Revolution Fibres team comes across any common misconceptions with masks/filter media. If so, I would love to hear what misconceptions they encounter.

Personally, I often encounter the misconception that the smaller the particle, the more likely it is to penetrate. However, the reality is that the MPPS is the most penetrating particle and these are often larger.

Answer – Melt blown is cheap and hence the go-to filter. They can meet the standards while having low breathability and non-reusability. Another thing we found is that we often have people inquire about “how small (particle size) can you masks filter?’. We found out that a nanofibre mask is capable of effectively filtering down to 0.05um – what they don’t know is, it is harder to filter particles at 0.3um than at 0.05um. Refer to Q8.

Final Notes

I hope that you enjoyed this interview with one of the foremost companies in nanofibre filtration. It was a fantastic opportunity to be able to ask questions directly to experts and to learn in the process. I would like to personally thank everyone at Revolution Fibres who helped answer my questions.

Want to learn more about Revolution Fibres? Make sure to check out their website. If you are interested in checking out masks that use their nanofibre technology I have already reviewed two – Metamask and Bloo Mask.

Have Questions or Comments?

Join the discussion on the BreatheSafeAir Community Forum. Ask any questions you have about air quality or adjacent topics and get quick answers!

https://craftcadence.com/nanofibre-versus-melt-blown-mask-filters-why-n95-n99-filters-are-not-all-created-equal/

Repeats same info you have above, then announces new mask release for May of 2021 with certifications for Viral filtration. Looks promising

Hello Jeanine,

I am actually about to publish a review for that mask tomorrow!