This article was written in collaboration with Lisa Bonner and Sarah Smit from Nelson Laboratories. Lisa Bonner is the Laboratory Operations Manager for Protective Barriers, and Sarah Smit is the Director of Laboratory Operations. Sarah is also chair of the subcommittee on biological protection (F23.40) at ASTM. I want to thank Lisa, Sarah, and Kate personally for providing invaluable assistance with ensuring this article is detailed and accurate.

ASTM F3502-21 is a Barrier Face Covering standard introduced in 2021 after the pandemic highlighted a flaw with respiratory protection standards. While healthcare and industrial users had many masks and respirators targeted for their use (such as NIOSH’s N95-P100 respirators), the general public lacked a standard to which general-use masks could be assessed.

While respirators, such as those approved by NIOSH, are tested to stringent standards, they aren’t designed for use outside of occupational settings. Not only are NIOSH respirators intended to be used only with professional fit-testing, but they emphasise filtration often at the cost of breathability and comfort.

Furthermore, NIOSH tests respirators such as N95s based on the assumption that they will be worn for only eight hours or less. Of course, it isn’t feasible for most of us to replace our masks and respirators after every use. While it’s since been found that most respirators can continue to perform outside of the eight-hour test period, the NIOSH respirator standards do not test re-use.

On the other end of the spectrum are cloth masks, which the CDC recommended for non-healthcare users at the beginning of the pandemic. However, these were quickly found to provide minimal protection as they had no standards setting guidelines for them to adhere to.

ASTM F3502-21 was created to address this gap between cloth masks and respirators and to provide consistent requirements for filtration devices used by the public during Covid. It sets performance requirements in the form of filtration and breathability while also emphasising elements essential to general use, such as reusability.

The ASTM F3502-21 standard is available for free on ASTM’s website. You will need an account to view the standard, but accounts are free to make and can be made in 60 seconds. If you want to delve deeper into the standard, I recommend reading the official documentation. However, if you want to get an overview of the standard, this article will provide you with all the information you need to know.

Subscribe to BreatheSafeAir

Air pollution is a silent killer that affects millions of people worldwide. Start protecting yourself today.

This post contains affiliate links. For more information, please refer to my affiliate disclaimer.

Information on this blog is for informational purposes only. Readers are encouraged to confirm the information herein with other sources. Furthermore, this information is not intended to replace medical advice from professionals. This website assumes no responsibility for the accuracy of the information, which is subject to change without notice.

What Are Barrier Face Coverings?

The AusAir AirWeave is an example of a Barrier Face Covering tested to ASTM F3502-21.

As per ASTM’s words, ASTM F3502-21 was ‘primarily established in response to the global COVID-19 pandemic beginning in 2019 to address a product that is neither a medical face mask per ASTM Specification F2100 for providing source control nor a respirator for providing inhalation protection as defined by regulatory requirements specified in the United States under 42 CFR Part 84’ (ASTM Designation F3502-21).

This gap between 42 CFR Part 84 (to which respirators such as N95s are approved) and ASTM F2100 (to which surgical masks in the U.S. are approved) meant there was no consumer-facing standard for face coverings or masks. F3502-21 was designed to bridge this gap by approving source-control devices that are comfortable enough for users to wear for long periods.

On top of providing source control, ASTM F3502-21 barrier face coverings are also intended to provide a degree of particulate filtration to the wearer. For this reason, F3502-21 face coverings are tested to a modified version of NIOSH’s filtration standard and must also be able to fit various facial dimensions.

In other words, ASTM F3502-21 barrier face coverings are primarily source-control products offering a degree of particulate filtration. They provide significantly less protection than a respirator, but they’re also designed to be worn without fit testing (which respirators require) and to be comfortable and reusable.

With that question answered it’s also important to discuss what barrier face coverings are not. Barrier face coverings are not respirators and should not be used in any situation where respirators are required. Barrier face coverings also don’t provide a high level of protection to the degree of respirators and are designed to reduce the spread of airborne viruses via source control. As such, they shouldn’t be used for protection against air pollution.

ASTM F3502-21 Requirements

ASTM F3502-21 requires pillars to be met, each with different performance criteria. The first of these pillars is protection (fit and filtration), followed by comfort (breathability) and reusability. MakerMask has a fantastic article which dives deeper into each of these criteria.

| Performance Criteria | Test Type | Standard |

|---|---|---|

| Filtration | NaCI particles at 0.3μm | TEB-APR-STP-0059 |

| Fit | Design assessment | ASTM F3407 (optional) |

| Breathability | Airflow resistance | TEB-APR-STP-0059 (with aerosol challenge turned off) |

| Reusability | Filtration, fit and breathability testing after the mask has reached the maximum number of wash cycles as defined by the manufacturer. | N/A |

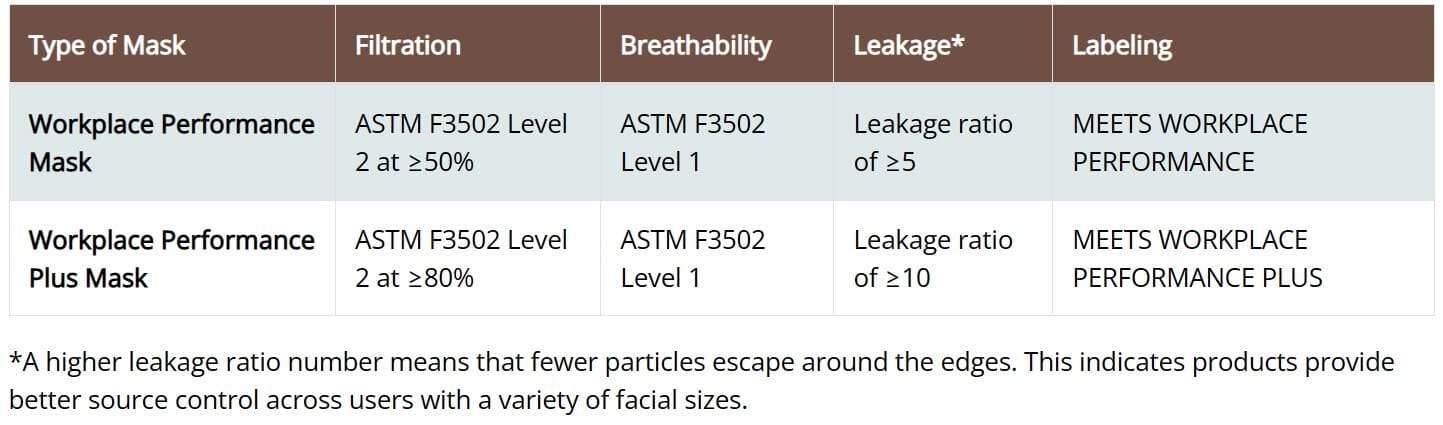

ASTM F3502 has two different levels by default – Level 1 and Level 2. Level 1 is the base level, and Level 2 is more stringent, with significantly stricter breathability and filtration requirements. On top of Level 1 and Level 2, there are other levels which other organisations have introduced. For example, NIOSH has created two more classifications: Workplace Performance and Workplace Performance Plus.

We will discuss the differences between these classifications in the respective sections below. However, it’s important to remember that Level 1, Level 2, Workplace Performance, and Workplace Performance Plus are all different performance levels of ASTM F3502-21. ASTM designates Levels 1 and 2, while NIOSH designates the Workplace Performance standards.

Filtration

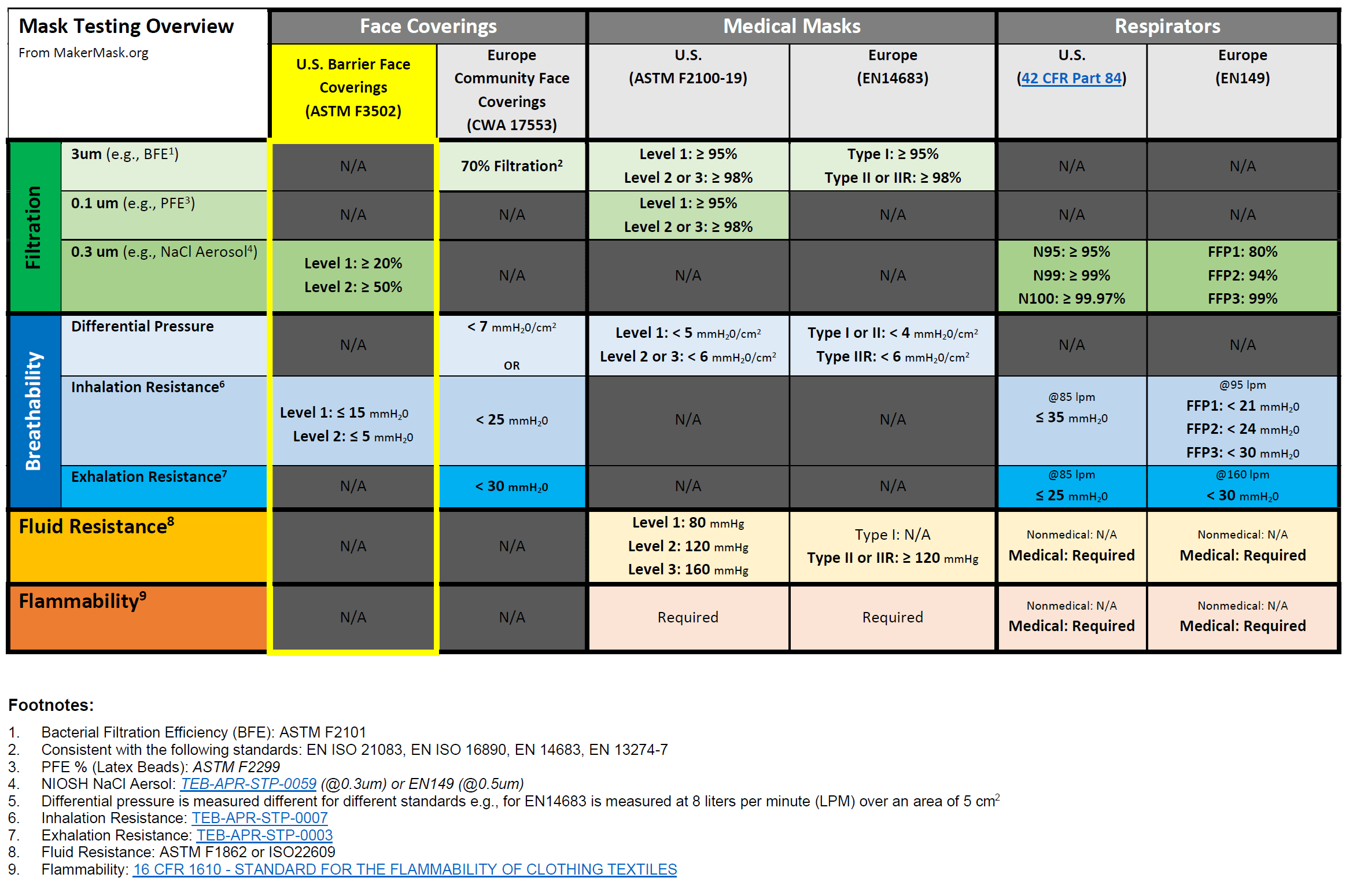

Filtration for ASTM F3502-21 barrier face masks is measured using a particle filtration efficiency (PFE) test. In a recent article, I wrote about how particle filtration efficiency tests typically aren’t directly comparable. Across different PFE and respiratory protection device tests, many methodologies exist, including different challenge particle types and sizes, varying conditioning parameters, and more.

However, PFE testing for ASTM F3502-21 uses the NIOSH test methodology from TEB-APR-STP-0059. This is the same PFE procedure by which N95 respirators are tested. TEB-APR-STP-0059 is a stringent PFE test, and it challenges masks and respirators with 0.3μm, charge-neutralised, NaCI particles.

0.3μm is the most penetrating particle size for the filter media used in most respiratory protection devices meaning this test is a worst-case situation for the filter. Both particles smaller and larger than 0.3μm will be filtered with greater efficiency.

While the testing procedure is the same with NIOSH N95s, the most significant difference is in the filtration performance required. Where an N95 is required to have ≥ 95% filtration, ASTM F3502-21 only requires ≥ 20% filtration for Level 1 and ≥ 50% filtration for Level 2.

To fully conform to ASTM F3502-21, a product must meet a filtration efficiency of ≥ 20% for Level 1 and ≥ 50% for Level 2 performance. However, with ASTM F3502-21 only classifying Level 1 and Level 2 masks, NIOSH has also created two more performance recommendations: Workplace Performance Masks and Workplace Performance Plus Masks.

| Performance Property | Level 1 | Level 2 | N95 |

|---|---|---|---|

| Filtration | ≥ 20% | ≥ 50% | ≥ 95% |

Workplace Performance Masks are required to meet Level 2 filtration (≥ 50%), whereas Workplace Performance Plus Masks are required to achieve ≥ 80% filtration using the same test (TEB-APR-STP-0059). These two additional classifications also have breathability requirements which I will discuss in the next section.

| Type of Mask | Workplace Performance Mask | Workplace Performance Plus Mask |

| Filtration | ≥ 50% | ≥ 80% |

Fit

ASTM F3502 requires manufacturers to provide a leakage assessment. While this can be performed under a Total Inward Leakage Assessment under ASTM F3407, they can also conduct this through a design analysis of their product and are not required to provide quantitative data with this. This design analysis shows that the barrier face covering can provide adequate coverage for various faces of different dimensions.

N95 respirator wearers must undergo a fit test to verify the respirator is sealing to their face. Although wearers of barrier face coverings are not required to undergo this test, there is still an expectation that there is a way to secure the covering for the length of time it is in use. Examples of these could include ear loops, a head harness, a nose bridge, etc., as long as all fixtures allow for user adjustability.

Workplace Performance Mask requirements. CDC.

While ASTM F3502 Level 1 and Level 2 masks have TIL (total inward leakage) testing as per ASTM F3407 as an optional extra, Workplace Performance and Workplace Performance Plus Masks must undergo TIL testing (ASTM F3407-20). To pass, Workplace Performance Masks must have a leakage ratio of ≥ 5, and Workplace Performance Plus Masks require ≥ 10. The leakage ratio represents the number of particles outside the mask compared to the number inside the mask.

Breathability

One of the areas in which ASTM F3502-21 differs significantly from respirator standards is in breathability (airflow resistance) requirements. Respirators are not known for being easily breathable, and as ASTM F3502-21 barrier face coverings are intended for widespread use, comfort – and its biggest contributor – breathability, is critical.

Similarly to filtration, ASTM F3502-21 has two levels regarding breathability. For Level 1, barriers must have a resistance of ≤ 15mm H2O. For Level 2, this number drops to ≤ 5mm H2O. For comparison’s sake, N95 respirators must have an inhalation resistance of ≤ 35 mm H2O and an exhalation resistance of ≤ 25 mm H2O.

| Performance Property | Level 1 | Level 2 | N95 |

|---|---|---|---|

| Breathability (airflow resistance) | ≤ 15 mm H2O | ≤ 5 mm H2O | Inhl. ≤ 35 mm H2O Exhl. ≤ 25 mm H2O |

These airflow resistance requirements ensure both Level 1 and Level 2 barriers remain comfortable to breathe in even after long periods of wear. Respirators tend to have significantly higher resistance as the filter media used in these devices inherently increases airflow resistance. Even the most breathable N95 respirators I’ve tried, such as ElastoMaskPro, barely meet the ≤ 5 mm H2O airflow resistance requirement for ASTM F3502-21 Level 2.

On top of the Level 1 and Level 2 requirements set by ASTM, NIOSH also has a breathability requirement for its Workplace Performance and Workplace Performance Plus masks. Both of these classes of barrier face coverings are required to meet Level 1 breathability (≤15 mm H2O) as well as the aforementioned ≥ 50% and ≥ 80% filtration, respectively.

Where the filtration requirements set by ASTM F3502-21 are significantly less demanding than those for respirators (which generally require either ≥ 94% or ≥ 95% filtration), the airflow resistance requirements set by the ASTM standard are more strict. These priorities make sense since Level 1 and Level 2 barrier face coverings are intended as comfortable source-control masks.

Regarding standards and test methodology, breathability/airflow resistance for ASTM F3502-21 is measured at the same flow rate the filtration efficiency is tested with but with the aerosol challenge turned off. The highest measured resistance to airflow of all the tested specimens is used to determine the classification of the airflow resistance. This is a different test method than is typically used for N95 respirator breathability or medical face masks.

Reusability

Perhaps the biggest difference between previous mask and respirator standards and ASTM F3502-21 is the requirement for masks to undergo reusability testing. Where respirators are only intended for one-time use and are only tested as such, barrier face coverings undergo reusability testing.

Each mask under ASTM F3502-21 must include washing instructions. While these will vary from mask to mask, each ASTM F3502-21 mask must include extra care instructions. This includes the maximum number of cleaning cycles that can take place before the device can no longer safely serve its purpose, as well as exactly how you are expected to clean the product.

Masks are tested before and after the maximum number of laundered cycles specified by the manufacturer. The particulate filtration efficiency, breathability, and leakage testing before and after laundering ensure that any stretching, distortion, or damage during use by the wearer is accounted for.

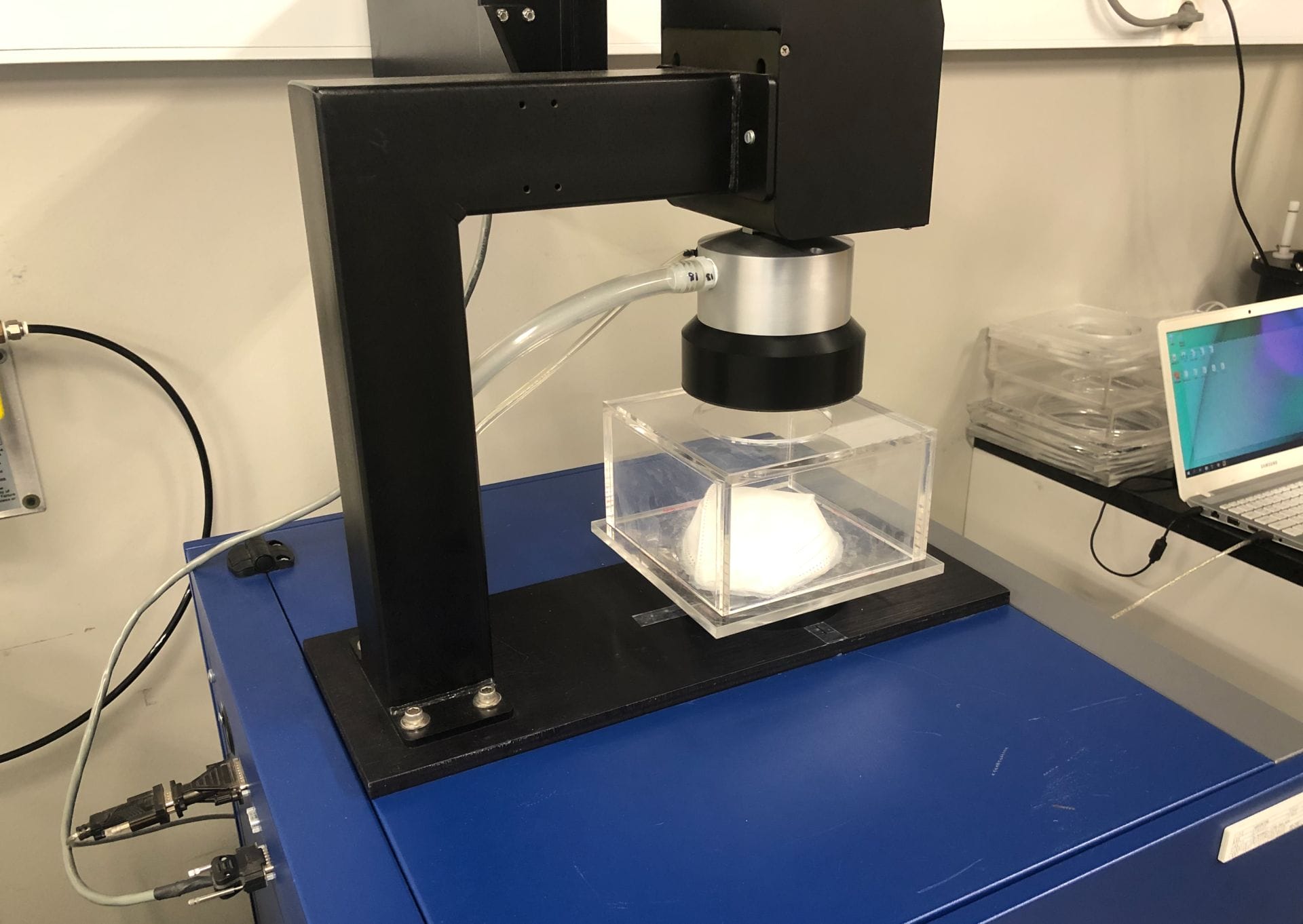

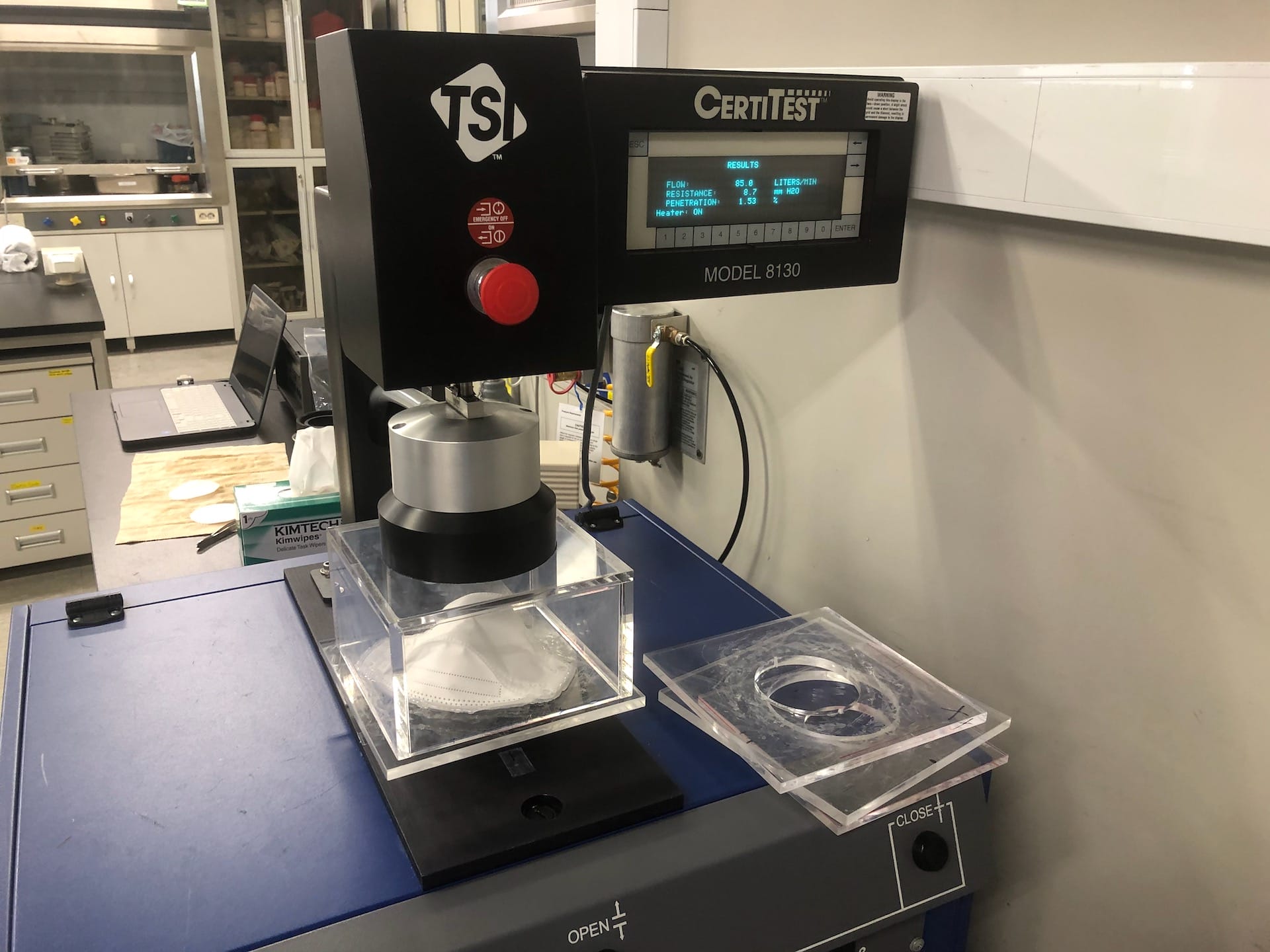

To ensure accurate testing, manufacturers must submit 10 test samples of each state (unwashed and washed to the max) to a laboratory such as Nelson Labs to certify to ASTM F3502.

ASTM F3502-21 vs N95 (42 CFR Part 84)

Table from makermask.org.

As I mentioned in the filtration section of F3502-21 requirements, not all particle filtration efficiency tests are comparable. Different tests use different challenge particles at different sizes, speeds, charges, and more. However, one benefit of the ASTM F35021-21 standard is that the particle filtration efficiency testing is carried out using the same test methodology NIOSH uses to approve N95 respirators as per TEB-APR-STP-0059.

It’s important to note that devices certified ASTM F3502-21 and NIOSH-approved respirators are NOT considered equal. A barrier face covering can not offer the same level of protection provided by an N95. With that said, at least regarding PFE, respirators and barrier face coverings undergo similar testing. Let’s look deeper at the NIOSH requirements compared to ASTM F3502-21.

Similarities

ASTM F3502-21 and TEB-APR-STP-0059 testing is similar in a few ways, including how the filter is mounted or sealed to a test plate, the conditioning parameters, and the aerosol challenge used for both test methods.

First, as both ASTM F3502 and N95 respirators are exposed to high humidity and temperature condition during use, both types of devices are conditioned at 85 ± 5% Relative Humidity (RH) 38 ± 2.5 °C for 25 ± 1 hour prior to being tested.

This conditioning helps mimic a used state for that device since humidity and temperature will be higher when worn on someone’s face as they breathe into the covering. This allows labs to gather the most accurate data on how it would perform when someone is wearing the covering.

Next, to test filtration efficiency consistently, devices for ASTM F3502 are mounted to steel plates using the same method used for sealing N95 respirators for testing. Both test methods are similar in that they use the same type of machine, which uses a 2% sodium chloride suspension as the challenging aerosol.

Nelson Labs uses a TSI Test Unit, which produces a 0.26 µm aerosol. This is generally accepted to be the most penetrating particle size, which is why it makes an excellent choice for testing, where labs can recreate the worst-case scenario for the end user of the respirator or covering.

Testing this worst-case scenario ensures the product will keep the end user as safe as possible, even against the most severe possible exposures they could be facing, even their co-worker in the office who never seems to stop sneezing.

Lastly, ASTM F3502 also replicates the NIOSH flow rate of 85 L/min when testing an entire, mounted device. These rigorous test conditions provide a more challenging test for coverings than most other filtration tests required for other devices.

Differences

One of the biggest changes when testing a barrier face covering is the duration of time barrier face coverings are exposed to the sodium chloride aerosol. ASTM F3502 calls for a measurement time of only 4-15 seconds for all ten samples. N95 respirators, on the other hand, are required to undergo a 200mg load test for the first three samples of the test set.

This means that the test runs until 200mg of sodium chloride has contacted the filter, which is a variable length of time depending on the exact concentration of the sodium challenge within the machine’s tank and the machine itself. Within Nelson Labs, these load samples take about 2 hours to run. The remaining 17 samples within the 20-sample set are typically tested for about 1 minute.

All NIOSH devices must be tested as a complete product and will always be mounted and tested at 85 L/min. ASTM F3502 also requires samples that are formed into a dome, contain seams down the middle, or are shaped into duckbills to be mounted and tested at 85 L/min.

However, when a sample can be spread out and flattened into the sample holder, such as your typical pleated face mask, ASTM F3502 instructs testers to adjust the flow rate to account for the reduced surface area they are testing. For example, a filter with a surface area of 100 cm2 would be tested at 60 L/min.

This is due to the face velocity, which measures the speed at which air enters the covering. The ASTM F3502 standard requires a face velocity of 10 ± 0.5 cm⁄s whenever not testing at 85 L/min. This ensures all face coverings are treated equally because an 85 L/min test is harsher when testing against a smaller surface area.

The Future of ASTM F3502-21

ASTM F3502-21 is a good step towards creating a more inclusive masking standard. However, it’s not a perfect standard, and there is room for improvement. One key area that I believe needs to be improved is the filtration requirements. With a requirement of only ≥ 50% filtration for Level 2, I still see a vast gap in current standards.

Luckily, improvements have already been made to ASTM F3502 since it was released. As discussed in earlier in the article, NIOSH has created an additional category outside of the ASTM F3502 standard titled “Workplace Performance Plus Mask”, which has the highest filtration category of ≥ 80%. This has gone a long way towards bridging the previous performance gap.

Other improvements could also be made to the standard. For example, one improvement would be to separate the test method from the standard specification. For example, ASTM F3502 is now cited as the required test method for sub-micron filtration efficiency in ASTM F2100, the standard for medical face masks.

Sharing a test method does not necessarily mean that standards for different products will share the same performance requirements. Keeping the requirements and specifications for each product type separate from the test method used to obtain those results is helpful and reduces confusion for manufacturers and product users alike.

ASTM F3502-21 FAQ

What Is ASTM F3502-21?

ASTM F3502-21 is a barrier face mask covering standard created to address a lack of community-focused source control mask/respirator standards.

What Does ASTM F3502-21 Test For?

ASTM F3502-21 tests filtration, breathability, reusability, and fit (but TIL testing is not required).

What Is the Difference Between ASTM F3502-21 Level 1 and Level 2?

Level 1 requires that a face covering has more than 20% filtration and less than 15 mm H2O airflow resistance. Level 2 is more stringent and requires greater than 50% filtration and less than 5 mm H2O breathing resistance.

Can I Check the Validity of an ASTM F3502-21 Certification?

There is no central database for ASTM F3502-21. However, the CDC does maintain a database of face coverings submitted with third-party laboratory testing. It’s important to note, however, that these face coverings are not endorsed by NIOSH or the CDC.

Have Questions or Comments?

Join the discussion on the BreatheSafeAir Community Forum. Ask any questions you have about air quality or adjacent topics and get quick answers!